On these lathes, the spindle motor is a single rpm and direction motor, it sits on the end of a gearbox transmission with internal coils that operate clutches. Pull the spindle lever back to stop, the spindle slows down slowly, and into reverse, nothing, so we have no brake or reverse!

Ok, pull the spindle lever to forward, the spindle starts up, nice and quite, smooth! grab the joystick and twist it, it goes through all 4 gears perfectly, over to 0 and it coast down, stops but slowly still turns, you can stall the spindle.

the control wires went through an adjustable heater, took a screw driver and spun the adjuster back and forth a few times to make sure the contacts where clean, presto hit the switch, the spindle motor stays running! Open the electrical panel, checked all the fuses, they are all ok, hit the spindle motor switch again, release, the relay is not staying engaged, looked like the control contacts where arcing pretty good. pulled the plug, swapped 2 wires, back in, and now when you hold the switch in, spindle turns the right direction! pushed a few times same result, held it in and pulled the spindle lever one, spindle turns, wrong direction. Pushed the spindle motor switch, it turns up but once you let go the switch it kicked out. hit the coolant switch and the coolant pump works fine!! turned it of, got a new plug on end, plugged it in, turned the breaker on.

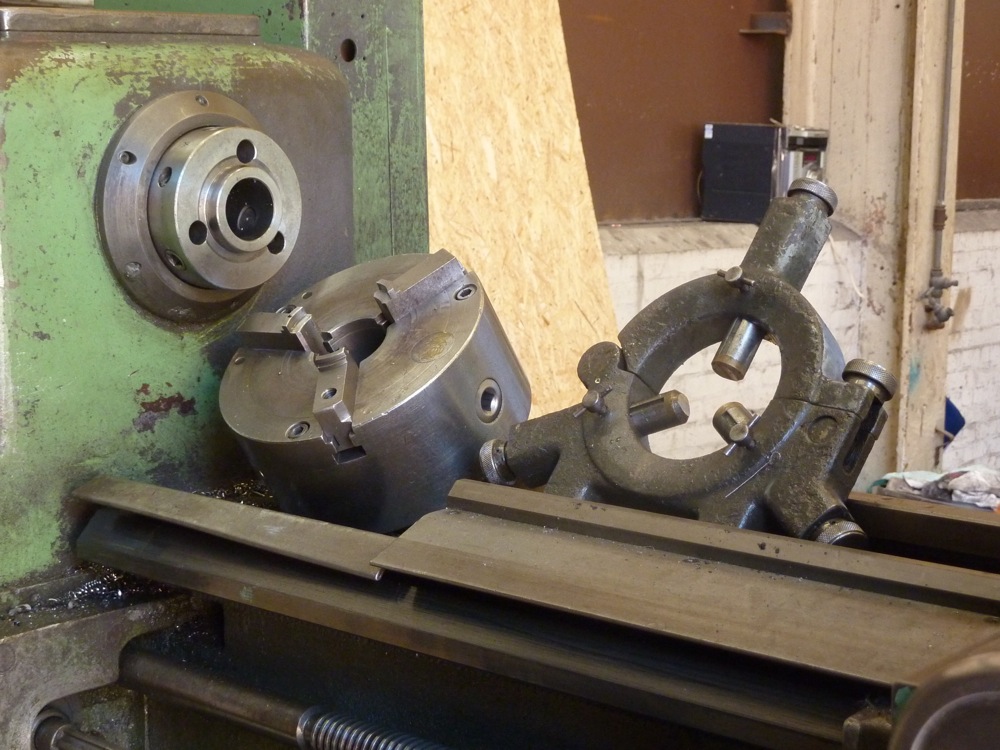

Ok, open the panel to figure voltage it needs, had a 120/208 plug on the end of the cord, first thing English electronics are about the worst you can find, well Italian is further behind them! there is transformer that takes 240/480 in and drops out 24 volt for the controls, the coolant pump is 240 and on its one line from line service, so figure 240 is good. the lathe has been repainted, but it is in very nice shape, no wear on ways! when he finally admitted what he paid for it, I just hung my head and wondered, very cheap lets say, they told him it had transmission problems, and that the machinist still used it periodically as it was stuck in the speed he needed? Goerge went and got the lathe, brought it over to my shop for e to fix it for him, I always like a new challenge! it showed up with a brand new high end 3 jaw chuck! aloris wedge tool post, and an interchangeable nose live center. My buddy George has been working on this deal for a few years, it finally bore fruit and he is the proud papa of a Graziano Sag 12 lathe.

0 kommentar(er)

0 kommentar(er)